During night-time driving, heavy rain, fog, and other low-visibility scenarios, the clarity of road markings directly determines driving safety. Traditional reflective studs, with their reliance on light reflection, susceptibility to damage, and limited battery life, have long represented an invisible hazard to road safety. The solar-powered road stud HA-RS-150 (IL300) precisely addresses these challenges, establishing itself as the preferred upgrade for road signage in municipal, motorway, and scenic area applications. Today, we examine five core dimensions to reveal the deeper reasons behind this product's recommendation.

‘Visibility’ is the core mission of road signage, and the HA-RS-150 (IL300) achieves breakthroughs in both brightness and visibility. Its LED light source strictly adheres to the IL300 international standard, delivering a luminance of 300 cd and a 120° beam angle. This means that even in pitch darkness, drivers can clearly see the warning light emitted by the stud from 500 metres away – a 2.5-fold improvement over the 200-metre visibility of standard reflective studs.

Calculated at the average motorway speed of 100km/h, a 500-metre visibility distance affords drivers at least 18 seconds of reaction time, sufficient to address scenarios such as ‘lane departure ahead’ or ‘sudden obstacles’. On urban roads, this advantage further reduces hazardous behaviours like ‘lane-cutting or sudden braking caused by unclear markings’. Field data from a motorway section demonstrates that installing the HA-RS-150 (IL300) reduced night-time lane departure incidents by 63%, conclusively validating its safety benefits through enhanced brightness.

The endurance of solar products remains a core concern for purchasers: ‘What if it doesn't illuminate on cloudy days?’ ‘What if slow charging causes nighttime outages?’ The HA-RS-150 (IL300) resolves these issues through core component upgrades.

Its high-efficiency monocrystalline silicon solar panel achieves 23% light-to-energy conversion (industry average approx. 18%). Under sunny conditions, just 4-6 hours of sunlight fully charges its large-capacity lithium battery, sustaining 10-12 hours of continuous illumination at night. Even during 3-5 consecutive days of overcast or rainy weather, the lithium battery maintains normal illumination without failing due to poor conditions. Compared to standard solar road studs offering merely ‘2 days of backup during cloudy weather,’ the HA-RS-150 (IL300)'s endurance better adapts to variable outdoor environments, making it particularly suitable for southern regions with frequent rainfall and fog.

Road studs endure hundreds to thousands of vehicle rolling daily while facing torrential rain, snow accumulation, and intense solar exposure. Durability directly determines cost-effectiveness. The HA-RS-150 (IL300) achieves industry-leading standards in material selection and protective design.

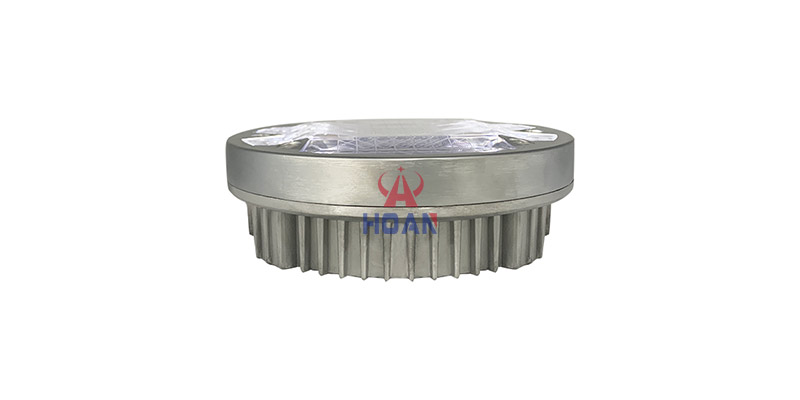

The housing employs aerospace-grade aluminium alloy, forged and anodised to achieve 30-tonne compressive strength – ensuring no deformation or cracking even under repeated heavy lorry rolling. The surface anti-corrosion coating resists UV radiation and acid rain erosion, maintaining colour and integrity during prolonged outdoor exposure. Concurrently, the product achieves the highest IP68 waterproof rating. Its fully sealed internal circuitry prevents moisture ingress even when submerged in road flooding, thereby avoiding short-circuit failures.

According to Henan Hao'an's after-sales data, the HA-RS-150 (IL300) boasts an average service life of 5-8 years – over four times longer than conventional plastic studs (typically lasting 1-2 years). Requiring virtually no maintenance during operation, it substantially reduces municipal departments' costs associated with frequent replacements and labour-intensive repairs, delivering genuine ‘one-time investment, long-term peace of mind’.

Road scenarios demand vastly different installation and functional requirements for studs: new roads necessitate embedded installation, operational roads cannot tolerate surface disruption, while bends and gradients require dynamic guidance... The HA-RS-150 (IL300) achieves ‘universal adaptability’ through its flexible design.

Regarding installation methods, the product supports both ‘screw-fixed’ and ‘embedded installation’ options: For operational motorways and urban roads, no road-breaking is required. Using the supplied 14PCS/6PCS screws, each stud can be fixed in just 10 minutes without disrupting traffic flow. For new road construction, installation channels can be pre-reserved. Embedded installation ensures flush alignment with the road surface, preventing jolts from vehicle rolling.

More practically, its ‘synchronised flashing’ function enables multiple studs to link wirelessly, emitting light in unison at preset intervals (e.g., once per second) to form a ‘dynamic guidance line’. In hazardous areas like mountain bends, motorway junctions, and construction zones, this dynamic guidance provides a more intuitive warning for drivers to ‘slow down and change lanes,’ enhancing warning effectiveness by over threefold compared to static lighting. Following installation on a scenic mountain road, visitors reported feeling ‘greater reassurance at night seeing the synchronised flashing studs, eliminating concerns about poor visibility around bends.’

Today, the ‘dual carbon’ goals have become a key guiding principle for transport infrastructure development, making the ‘green credentials’ of the HA-RS-150 (IL300) a significant recommendation factor. The product operates entirely on solar energy without requiring external grid connection. Each stud saves approximately 12 kWh of electricity annually. Installing 100,000 units along a city's main thoroughfares could reduce annual electricity consumption by roughly 1.2 million kWh, equivalent to cutting 960 tonnes of carbon dioxide emissions. This aligns perfectly with the development direction of ‘green transport and low-carbon cities’.

Furthermore, the manufacturer of the HA-RS-150 (IL300), Henan Hao'an, is a seasoned enterprise with 15 years of specialisation in traffic infrastructure. It holds multiple patents related to solar-powered road studs and offers customisation services (such as adjusting light colour and flashing frequency according to client requirements). Purchasers not only receive premium products but also benefit from after-sales guarantees including a ‘three-year complimentary warranty and lifetime technical support,’ thereby avoiding the difficulties of post-purchase disputes associated with substandard products. The official website's ‘Super September Promotion’ (1st–30th September) is currently underway, with exclusive discounts available for bulk purchases, further enhancing value for money.

The value of road signage lies not merely in its presence, but in its ability to function effectively when it matters most. HA-RS-150 (IL300) elevates road signage from ‘passive reflection’ to ‘active protection’ through five key advantages: high brightness, extended endurance, wear resistance, universal compatibility, and eco-friendliness. This innovation resolves numerous shortcomings of traditional road studs while meeting modern traffic demands.

If you represent municipal transport authorities, motorway operators, or are responsible for scenic areas or industrial parks seeking cost-effective road stud solutions for safety upgrades, visit Henan Hao'an's official website (https://www.haroadstud.com/) to explore detailed specifications and application case studies for the HA-RS-150 (IL300). Alternatively, enquire about promotional pricing via telephone (+86 0371 8888 6666), WhatsApp (+86 1933 716 3210) for promotional pricing. Selecting a reliable solar-powered road stud adds a solid layer of protection for every traveller's safety.