In the field of road safety, the smallest detail often determines a matter of life and death. Road studs, these roads on the inconspicuous but extremely important facilities, is like a loyal guardian, quietly guarding the safety of every road user. Among them, solar road studs with its unique features and significant advantages, increasingly become the leader in road safety facilities.

In the field of road safety, the smallest detail often determines a matter of life and death. Road studs, these roads on the inconspicuous but extremely important facilities, is like a loyal guardian, quietly guarding the safety of every road user. Among them, solar road spike with its unique features and significant advantages, increasingly become the leader in road safety facilities.

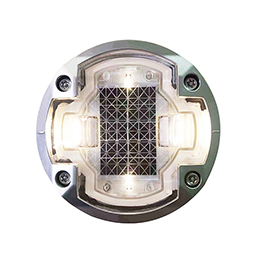

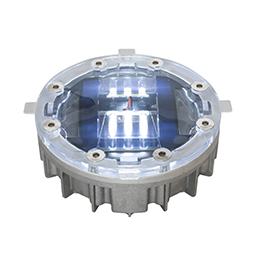

Solar road studs, the integration of solar energy technology and lighting, is a typical representative of advanced road safety devices. It is mainly composed of solar panels, LED lights, batteries and rugged shell. During the day, the solar panel is like an industrious collector, converting sunlight into electricity and storing it in the battery; at night or in bad weather when the light is dim, the battery releases electricity to drive the LED lights, illuminating the road, clarifying the road outline and direction, and escorting the road users.

solar road studs and reflective road studs

Reflective road studs rely on vehicle headlights, its internal reflective material reflective light to remind drivers. But in the absence of vehicle headlights, late at night when there are few cars or bad weather light is very dark, it basically can not play a role, it is difficult to effectively guide the road. Solar road studs active light, relying on its own solar power supply system, regardless of whether there are vehicles around, how bad the weather, can work stably. Professional tests show that its visual distance can reach up to 900 metres, so that drivers can see the road at a distance, greatly improving the reaction time and safety in complex road conditions.

Reflective road studs long-term exposure to the outdoors, facing vehicle crushing, natural erosion, heavy pressure to the surface wear and tear, rain, wind and sun so that the reflective material aging, reflective effect reduces the need for timely replacement, otherwise affect road safety. Frequent replacement of human and material resources, but also interfere with traffic. Solar road studs are durable, the shell is mostly made of aluminium alloy or special engineering plastics, anti-pressure, anti-impact, corrosion-resistant, able to withstand repeated crushing of vehicles and bad weather test. The internal components are carefully selected and designed for high stability. Maintenance, regular cleaning of solar panels to ensure that no dust and debris in order to efficiently absorb solar energy, and occasionally check the battery and LED light status can be, low maintenance costs.

Solar road studs work without pollution, in line with environmental requirements, and no electricity costs, long-term use of road management can save a lot of energy costs. Although the initial purchase and installation costs are higher, but the long-term comprehensive cost advantage is obvious.

Before installing solar road spike, detailed planning and precise site selection. Need to consider the type of road, traffic flow and hazardous areas and other factors. Sharp turns at the installation of studs, can warn drivers in advance to slow down, clear bend direction; pedestrian crossings can remind drivers to pay attention to pedestrians; low visibility road installation, can enhance the lighting. Comprehensive analysis to determine the installation location, give full play to its role.

Installation should be prepared materials and tools. Materials include different types and specifications of solar pins, which should be selected according to the needs, and epoxy resin adhesive to ensure that the pins are fixed. Tools include drills for drilling, as well as measuring tools to measure the installation position and spacing to ensure accurate installation.

First comprehensively clean up the road surface, remove debris, dust and the original road markings, to ensure that the installation surface is flat and clean, which is crucial to the road nails and road surface good bonding. Clean up according to the planning position with the marking tool to accurately mark the installation point.

With a drill according to the specifications of the road nails in the marking of holes, drilling depth and diameter should be strictly controlled. After the use of epoxy resin adhesive or mechanical fixing parts will be firmly installed in the hole, to ensure that the road spike and the road surface flush, not only beautiful and avoid additional impact by the vehicle to affect the life of the vehicle, and at the same time, carefully check whether the installation is solid.

After installing the spikes, connect the solar panel to the internal circuit to ensure a solid connection. Next, a full test is carried out to check whether the LED lights can light up normally, the charging status of the solar panel and the stability of the road spike. If found that the LED lights do not light, charging abnormalities and other issues, timely investigation and repair to ensure that the road spike formally put into use after the normal work.

Highway speed, traffic flow, in order to give drivers enough reaction time and long-distance visual guidance, solar road spike installation distance is generally set to 10 - 15 m. This spacing allows drivers to use the road spikes in the road. This spacing allows drivers to always see the road studs in front of them when driving at high speeds, accurately judge the road direction, and maintain a safe driving condition, avoiding visual fatigue due to prolonged straight-line driving and deviation from the lane.

Ordinary roads include urban and rural roads with relatively slow speeds and complex traffic flows. Urban road intersections, pedestrians, rural road conditions, poor lighting. Therefore, the installation distance of solar road studs is set at 5 - 10 metres to meet the needs of vehicles to identify road studs in close proximity to obtain road information, but also to ensure road consistency and visibility, and to help drivers judge the road boundaries and driving direction in complex traffic environments.

Sharp turns, ramps and other visually restricted road sections, the driver's line of sight is blocked, the need for more intensive guidance, solar road spike installation distance shortened to 2 - 5 metres. In the sharp turns, dense road nails to remind drivers to slow down in advance, clearly show the direction of the curve outline; ramp, close to the road nails for drivers to provide timely and accurate guidance to ensure that vehicles enter and exit smoothly.

Dangerous sections of busy traffic such as intersections, frequent vehicle interchanges, easy to cause accidents. In order to enhance the warning effect, solar road studs are installed at a distance of 1 - 2 metres. Dense road studs at intersections attract drivers' attention, so that they can slow down, stop or turn in advance to prepare for the reduction of accidents, and play a similar role as a signal light warning at unsignalised intersections, guiding vehicles to pass in an orderly manner.

Tunnels and bridges are special environments with restricted vision and complex road conditions. The light inside the tunnel is dark, and the bridge may be affected by strong winds. Solar road spike installation distance is set to 3 - 5 metres is more appropriate to ensure that these special sections of the road for the driver to provide effective guidance to protect vehicle safety, in the long tunnel, the reasonable spacing of the road spikes can provide drivers with continuous visual guidance to ease the sense of tension.

Solar panels are the core components of solar road studs, and their quality determines the service life of the studs. High-quality monocrystalline silicon solar panels have high conversion efficiency and a service life of up to 20 years under normal maintenance. Low-quality solar panels are prone to aging, reduced conversion efficiency, shortening the overall life of the spike, so the choice should focus on the quality of solar panels.

Batteries are responsible for storing energy in solar spikes. Commonly used lithium-ion battery life of 3 - 5 years, high-end models using advanced technology, life can be extended to 8 years. Battery life is affected by a number of factors. At extreme temperatures, high temperatures accelerate chemical reactions and reduce battery capacity; low temperatures reduce battery activity and affect charge/discharge efficiency. Frequent charging cycles also deplete battery life. Therefore, when choosing solar road studs, try to choose products equipped with high-temperature-resistant batteries.

As a light source, LED lamps usually have a lifespan of 50,000 to 100,000 hours and can last for several years under normal use. Its low power consumption and low heat generation help to prolong the service life. However, high humidity, dust and other harsh environments will affect its durability, humidity may cause internal circuit short circuit, more dust affects heat dissipation. Therefore, solar studs are often designed to be waterproof and dustproof (IP68 rating) to protect the LED lights from working properly in harsh environments.

The shell material of solar spikes plays a key role in protecting the overall life of the spikes. Aluminium alloy or polycarbonate and other high-quality shell materials to resist corrosion, impact resistance, wear-resistant. Aluminium alloy shell oxidation, corrosion resistance, in the humid, salty environment is not easy to rust; polycarbonate shell impact resistance, can withstand the heavy pressure of vehicles and external impact. Sturdy shell to protect the internal components from physical damage, to ensure that the spike in the harsh environment of normal work, to extend the overall service life.

Regular maintenance is the key to extend the service life of solar road studs. To regularly clean the surface of the solar panel, dust and dirt blocking sunlight, reducing the conversion efficiency, available clean soft cloth or brush gently wipe. Also check the battery performance, observe the charging and discharging situation, there are abnormalities in a timely manner. At the same time to ensure that the LED lights work properly, check whether it is damaged or insufficient brightness. Through regular maintenance, timely detection and resolution of potential problems, to avoid premature damage to the spike due to minor faults.

Environmental factors have a significant impact on the life of solar spikes. High humidity environment, water seepage into the spike internal, resulting in electronic components rust, short circuit; strong rainfall impact spike affect the stability; prolonged exposure to sunlight so that the shell material aging, deformation. Installation should choose the right location to avoid the spike in a humid or sunny environment. If you can not avoid the harsh environment, you can choose the solar road studs designed for harsh environments, which uses more advanced protection materials and processes, can better adapt to the environmental challenges, to extend the service life.

In the highway and dual carriageway highway, red road studs set in the left edge of the road. Its eye-catching red colour can attract drivers' attention in all kinds of light conditions, and its main function is to warn drivers to pay attention to the road boundary and prevent vehicles from deviating from the road edge and causing accidents. At night or in inclement weather, the red road studs clearly outline the left side of the road, providing drivers with a clear driving reference.

Amber-coloured Road Studs

The amber coloured dowel is commonly found in the central divider of motorways and dual carriageway roads. It indicates the centre of the road and helps drivers to stay in the correct lane. On roads with high traffic flow, it can effectively separate traffic flows in different directions and avoid collision of vehicles due to lane confusion. Its unique amber colour is highly visible in low light conditions, providing drivers with clear road layout information and guiding safe driving.

Green Road Studs

In poorly lit areas, such as the countryside, green road studs are used to mark the edge of the road and guide drivers to the direction of the road. In rural lanes without street lights, green road studs are like lighthouses in the darkness, helping drivers to stay on the right road at night or when the light is dim, avoiding vehicles from leaving the road and falling into danger, and sometimes also indicating safe crossing areas to protect pedestrian safety.

White Road Studs

In urban areas with heavy traffic, white road studs are used to mark the edge of the road and guide drivers to drive safely. Urban traffic is complex, vehicle speed, lane changes are frequent, white road studs help drivers accurately judge the road boundaries, to keep driving in the correct lane, to ensure that vehicles in the busy traffic in a safe and orderly manner. At night or in bad weather, the bright colour of white road studs clearly shows the road contour, providing reliable visual guidance.

Yellow Solar road studs

In the central divider of dual carriageway roads and motorways, yellow road studs separate opposing traffic flows. Its eye-catching yellow colour is highly recognisable and can clearly delineate the lane boundaries under various weather conditions, guiding drivers to drive safely. In the road of heavy traffic flow, it can effectively avoid the collision of opposite vehicles misjudging the lanes and ensure the road traffic safety.

Henan Hoan Traffic Facilities Co. has excellent performance in the field of manufacturing solar road studs. The company produces reliable solar road studs, using high-quality materials and advanced production processes to ensure product durability and lighting effect. The company is certified by a number of industries and meets stringent standards for quality and safety. It is able to provide customised solutions for customers' individual needs. With years of industry experience, it has accumulated a good reputation and provided reliable products for many road projects. Meanwhile, its comprehensive after-sales protection system, including product warranty, quick repair and technical support, gives customers more peace of mind when purchasing and using the products.

VIII. Conclusion

As an important part of road safety facilities, solar road studs play a significant role in enhancing road safety by virtue of their unique working principle, diverse type characteristics and significant advantages. From the efficient use of energy to long life and durability, from environmental protection and energy saving to intelligent control, each feature creates safer and more reliable travelling conditions for road users. The careful planning and strict operation of the installation process ensures that they function accurately; the reasonable installation distance setting is suitable for different road types and special road sections to enhance road visibility and safety. Understanding the life span of each component of solar road studs and the factors affecting them will help you choose high-quality products and maintain them effectively to prolong the use cycle. The specific meanings and functions of different coloured road studs provide drivers with clear and accurate road information. When choosing a manufacturer of solar road studs, a combination of quality, certification, customisation, experience, reputation and after-sales warranty will ensure that you are sourcing a high quality product. Quality manufacturers such as Henan Hoan Traffic Facilities Co. provide a reliable choice for the market. With the development of technology, solar road studs will continue to play an important role in the field of road safety, contributing to a safer and more efficient traffic environment, which deserves to be actively adopted and promoted by road construction and management departments.