In the road traffic system, safety is a top priority. From the streets of bustling cities to the back roads of remote villages, any negligence in road safety can lead to catastrophes. Road studs, a small but critical road safety feature, play an important role in ensuring traffic safety. Solar LED Road Studs (Solar LED Road Studs), as an innovative product of the road studs family, is becoming a new favourite in the global road safety field with its outstanding performance and unique advantages.

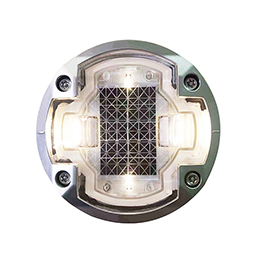

Solar panel is the energy core of the solar LED road studs, responsible for converting solar energy into electricity to power the LED lights. Its core material is mainly monocrystalline silicon and polycrystalline silicon. Monocrystalline silicon has a high energy conversion efficiency and good durability, and can efficiently convert sunlight into electricity with stable long-term performance. Polycrystalline silicon is more economical, although the energy conversion efficiency is slightly lower, but the cost is lower, in the cost-effective requirements of a wide range of products.

To protect solar panels from harsh outdoor environments, they are often covered with a layer of transparent protective material, such as transparent polycarbonate (PC) or toughened glass. The high transparency of these materials reduces the blockage of light, allowing solar panels to fully absorb sunlight. At the same time, they are scratch-resistant and UV-resistant, which prevents the surface from being scratched or aging due to long-term UV exposure and ensures that the solar panels work efficiently for a long period of time.

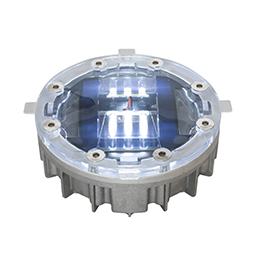

The shell of the solar LED studs has to protect the internal precision components and withstand vehicle crushing, so the choice of material is very critical. Aluminium alloy is a commonly used shell material, especially suitable for high-intensity road environment. Aluminium alloy has excellent compression resistance and can easily withstand repeated crushing by heavy vehicles without deformation. It is also corrosion-resistant and can be used stably in humid coastal areas or road environments with high salt content. In addition, aluminium alloy is lightweight and easier to install.

In addition to aluminium alloys, high-strength plastics such as polycarbonate (PC) or ABS plastic are also used to make the housing of the spike. Polycarbonate is impact-resistant, weather-resistant and stable in extreme environments such as high and low temperatures, effectively protecting the internal components, while ABS plastic has good toughness and strength, and performs well in occasions with low weight requirements, providing more choices for the design and application of road studs.

Energy storage batteries are responsible for storing energy in solar LED spikes. Currently, lithium batteries are a common choice. Lithium batteries have a high energy density and can store more power in a limited space. It has a long lifespan, generally up to several years, fast charging speed, can accumulate enough energy in a short period of time, to meet the demand for long-time lighting of the road spike at night. In addition, lithium batteries have excellent resistance to high and low temperatures, and can work stably in hot deserts or cold polar regions.

Nickel-metal hydride batteries are also common energy storage batteries. Although its energy density is not as high as lithium batteries, it has high safety and good cycle life. In cost-sensitive projects, nickel-metal hydride batteries are also widely used due to their cost-effective advantages.

LED lamps are the light source of solar LED studs, and their materials directly affect the luminous effect and service life.The core of LED lamps is a light-emitting chip made of semiconductor materials, commonly gallium nitride (GaN) and gallium phosphide (GaP). These semiconductor materials can efficiently convert electrical energy into light energy, high luminous efficiency, the service life is usually up to tens of thousands of hours, greatly reducing the number of times to replace the light source, reducing maintenance costs.

In order to protect the LED light chip from the external environment, it is usually encapsulated with a transparent encapsulation material. Epoxy resin or silicone resin is commonly used encapsulation materials, they are highly transparent, to ensure that the brightness of the LED lamp is not affected. At the same time, these materials are weather-resistant, waterproof and dustproof, which effectively protects the chip and extends the service life of the LED lamp.

The internal structure of the solar LED spike includes electronic components and circuit boards, which together form the control system of the spike and are responsible for energy management and automatic lighting. The circuit board is made of glass fibre reinforced printed circuit board (PCB). This material has good electrical conductivity, which ensures stable current transmission and normal operation of the spike. At the same time, it is heat-resistant and has high mechanical strength, which enables it to work stably for a long period of time in harsh outdoor environments and withstand unfavourable factors such as high temperatures and humidity.

In order to protect the internal electronic components from water vapour and dust erosion, the internal structure of the solar LED spike is encapsulated with sealing materials. Silicone and epoxy resin are commonly used sealing materials, they are waterproof and moisture-proof with excellent performance, which can effectively block the entry of external moisture and dust to ensure the safe operation of the internal electronic components.

In order to effectively indicate the road in unlit conditions, many solar LED road studs have built-in reflectors. The reflectors of road studs are usually made of polymethylmethacrylate (PMMA), which is a plexiglass material. PMMA has good optical properties and can reflect vehicle headlights efficiently, which significantly enhances the visibility of the road studs at night or in low-light environments, and provides drivers with clear road guidance.

Cat's eye, i.e. road reflector, is a common shiny circular device on roads and motorways. It works on the simple principle of passively reflecting the light from vehicle headlights and reflecting the light back into the driver's eyes, thus enhancing the visibility of road markings and edges at night, and has played a fundamental role in assisting drivers to drive safely for many years.

Solar LED Road Studs go beyond basic reflective functionality. It has an active light-emitting capability that utilises stored solar energy to emit light even in total darkness. Some Solar LED Road Studs can also sense ice, water, and other conditions on the road, providing data for road maintenance. Their bright LED lights and advanced design make them more visible than cat's eyes and represent a technological upgrade in road safety facilities, providing drivers with more reliable road guidance and enhancing safety at night and in inclement weather.

The Solar LED Cat's Eye collects solar energy during the day and illuminates at night, eliminating the need for batteries and wiring, making it green and environmentally friendly. Its LED light is bright enough to be recognised from a distance even under poor lighting conditions. Moreover, the design is durable and can withstand the test of bad weather and heavy traffic, and basically no maintenance is required after installation, which is widely used in some road scenes with high requirements for aesthetics and environmental protection, and further enriches the application forms of solar LED road lighting facilities.

Solar LED Road Studs need to be fully charged outdoors to achieve 200 + hours of uninterrupted signal at night (without additional sunlight exposure). It starts charging the first time it is exposed to sunlight and may take up to 8 hours to fully charge in full direct sunlight during the summer months. Charging time will be longer in areas of partial sun or shade, as insufficient light affects the efficiency of the solar panels' energy harvesting.

In winter and cloudy weather, the charging time for Solar LED Spikes can be significantly longer. This is due to the short daylight hours and weak sunlight in winter, and cloudy weather that blocks the sunlight. During this time, the spikes will work, but their uninterrupted operation will be shorter until they are fully charged for optimal performance. However, even when not fully charged, spikes can still function to some extent, providing basic lighting and guidance on the road.

The Solar LED Spike should be installed within 6 months of purchase, but if not, it should be kept charged outdoors. Prolonged discharging may damage the battery and reduce its performance and service life. When choosing a mounting location, make sure the product can be fully exposed to direct sunlight. Charging on the indoor window sill may be due to some coated glass blocking most of the daylight and affect the charging effect, so the choice of installation location is crucial to the normal use of road studs and performance.

The power generation efficiency of Solar LED Road Studs is directly affected by the light conditions. In full sunlight, it can generate electricity normally to ensure that the light at night. However, in rainy areas, insufficient light will result in the inability to generate electricity properly, which in turn will affect its normal operation. This high dependence on weather limits its use in perennially rainy areas, such as some tropical rainforest climates, where frequent rainfall makes it difficult for solar road studs to work stably.

Solar LED spikes are more costly than traditional spikes. Higher strength materials and high tech electronics are used to ensure performance, which drives up the manufacturing cost significantly. When it comes to large-scale installations, cost becomes an important factor that must be taken into account, and for some areas or projects with limited budgets, the higher cost may hinder the widespread use of solar LED spikes.

The operating hours of Solar LED Spikes are highly dependent on the performance of the built-in battery. With current technology, the battery life is usually limited and may need to be replaced every few years. If the battery wears out quickly, replacing the battery at a later stage will incur high maintenance costs, which not only adds to the economic burden, but may also affect the normal use of the road studs, leading to interruptions in road lighting and guidance.

Solar LED road spike because of the internal electronic components, the overall pressure resistance is relatively weak compared to ordinary road spike. Although the design of the pressure resistance factor, but in the face of excessive pressure, may not be able to withstand. After being crushed or hit by a car, the spike is easily damaged, affecting its normal work, requiring timely repair or replacement, which increases the maintenance workload and cost to a certain extent.

Installing too many solar-powered LED road studs on city roads or near residential areas may cause light pollution. Excessive light will affect the quality of life of residents and interfere with normal work and rest. For drivers driving at night, light pollution may also cause visual interference, bringing safety hazards, such as in some narrow streets or curves, too bright road stud lights may affect the driver's judgement of road conditions.

China as a solar product manufacturing country, the use of solar LED road studs is very high. The road management department actively adopts them on mountainous roads and busy traffic sections in cities at night. On highways, solar LED road studs can clearly delineate lanes and provide accurate guidance for vehicles travelling at high speeds. On urban main roads, it can assist traffic signals and guide vehicles to pass in an orderly manner. In mountainous roads, tunnels, sharp turns, frequent hazy weather areas, solar LED road studs are playing an important role in improving the safety of these complex road traffic.

The United States in California, Texas and other large states on the highway widely used solar LED road spike, for night traffic signs to strengthen. At lane separations on highways, solar-powered LED road studs can clearly differentiate between different lanes and avoid vehicle mix-ups. At entrance and exit signs, it allows drivers to prepare in advance for safe entry and exit from the motorway. In urban ITS systems, solar LED road studs work in tandem with other traffic facilities to significantly improve driving safety at night or in bad weather, helping drivers to stay alert and accurately identify lanes when driving long distances.

As the birthplace of the cat's eye, the UK is also actively using solar road stud technology to improve road safety. On many rural roads and unlit suburban roads, a large number of solar road studs have been installed to replace traditional reflective road signs. On rural roads, solar-powered LED pins illuminate the road for residents travelling at night. On suburban roads, they alert drivers to road boundaries and bends. On footpaths, solar-powered LED road studs provide safety guidance for pedestrians, effectively reducing the number of traffic accidents at night.

Australia's vast geography means that solar-powered LED road studs are commonly used on rural and long-distance roads. On long motorways, solar-powered LED road studs are illuminated at night to help drivers stay in the right lane during long drives. On poorly lit roads in remote areas, they provide drivers with clear road guidance. In bad weather, such as heavy rain, sand and dust, solar LED road studs can still play a role in ensuring driving safety. It is mainly used on highways and country roads, especially on unclear traffic signals or dangerous roads, providing a reliable safety guarantee for Australian road traffic.

South Africa has a high incidence of traffic accidents, especially on roads with heavy traffic at night. To improve the situation, solar-powered LED road studs have been installed on many major roads. On rural roads, solar-powered LED road studs provide light and guidance for vehicles travelling at night. On unlit motorway sections, they enhance road visibility and alert drivers to road conditions. Near pedestrian crossings, the solar-powered spikes warn drivers of pedestrians and provide clear visual guidance, significantly reducing the incidence of traffic accidents at night.

New Zealand is a mountainous country with winding roads, and solar-powered LED road studs play an important role on its motorways and mountain roads. At sharp bends on mountainous roads, solar-powered LED road studs can alert drivers to slow down in advance to ensure safe passage through the bends. On roads with poor visibility, they provide drivers with a clear outline of the road, helping them to accurately judge road conditions. On coastal roads, solar-powered LED road studs are able to withstand sea winds and humid conditions and work stably, effectively reducing the incidence of accidents on dangerous roads and ensuring driving safety.

The road traffic situation in India is complicated, and the problem of insufficient lighting at night is serious at the junction of urban and rural roads. In order to improve the situation, the government promotes the use of solar-powered LED road studs on roads and main roads in many provinces. On peripheral roads around the city, solar-powered LED road studs can help vehicles pass in an orderly manner and ease traffic congestion. On rural roads, they provide light for residents travelling at night. In congested areas, solar-powered LED road studs provide drivers with a clearer understanding of road conditions, improve night-time traffic efficiency and bring more safety to road traffic in India.

The Philippines has been actively promoting the use of renewable energy in transport facilities in recent years. Due to its tropical climate and long sunshine hours, solar-powered LED road studs have become an important part of the road lighting and signage system. On highways, solar-powered LED road studs provide steady illumination and guidance for long-distance vehicles. On urban roads, they can assist in traffic management and improve the efficiency of road traffic. On roads near tourist areas, solar LED road studs can provide safety for tourists, enhance the night safety of these areas, and also comply with the Philippines' environmental policy objectives. Safer and more efficient.

Solar LED road studs are designed to provide illumination and road marking without interfering with traffic. They have a smooth surface and are usually embedded in the road with a small exposed portion. High-strength materials such as aluminium alloy or polycarbonate are used, which can withstand vehicle crushing without deformation. Designed to be no more than 25mm high, this low height design reduces the impact on the vehicle chassis and tyres. During normal driving, the tyres come into contact with the studs safely and without damage, ensuring a smooth and safe ride.

The location and method of installation directly affects the potential damage to tyres. Many solar powered LED road studs are recessed, partially embedded in the road surface, with the exposed portion used only for illumination, ensuring that they do not rise above the road surface, reducing the potential for tyre collisions. When installed, the spacing will be reasonably arranged according to the road conditions and traffic flow to avoid vehicles frequently running over the studs. The reasonable installation method reduces the potential risk of road studs to tyres from the source and protects the safety of road users.

Based on the design and installation considerations, under normal circumstances, solar LED road studs will not damage tyres. The materials have been rigorously tested to withstand high-strength pressure and have no sharp protrusions to puncture or damage tyres. The low height design makes the impact force low when the tyre is crushed and will not damage the tyre structure. Qualified products have a smooth surface with no dangerous protruding parts or edges, which reduces tyre wear. In actual use, a large number of road tests and user feedback have proved the safety of solar LED studs for tyres.

Although Solar LED Spikes are safe under normal conditions, there are special circumstances. Non-standard products may have sharp edges or excessive protrusion due to substandard materials or poor design, posing a potential threat to tyres, so it is vital to purchase and install a qualified product. If the spike is damaged by external forces or is not securely installed, it may result in bulging or loosening of components, affecting the vehicle's movement, in which case it needs to be maintained and repaired in a timely manner to prevent potential damage to the tyres. Users in the use of the process, should also pay attention to the condition of the spike, found that the problem of timely feedback, and jointly maintain road safety.

Solar LED road studs with unique composition materials, in energy conversion, protection, lighting and other aspects to show the advantages. Compared with traditional cat's eyes, it has more powerful functions and visibility. Its charging method is affected by the weather, but in most environments can meet the needs of use. Despite some drawbacks, such as weather dependence and high cost, it plays an important role in enhancing road safety in different road scenarios in many countries around the world. Moreover, it has no impact on vehicle tyre safety under normal conditions.

Road builders, managers and relevant authorities should actively adopt solar-powered LED road studs in suitable scenarios to give full play to their role in road safety. At the same time, manufacturers are called upon to continue to improve technology, reduce costs, enhance performance and solve current problems. Through the joint efforts of all parties, we will promote the wider and more effective application of solar-powered LED road studs in the field of road safety, contributing to the cause of global road safety and making road traffic safer and more efficient.