Road safety facilities is to protect the cornerstone of traffic safety, it is like a silent guardian, in our daily travel plays an indispensable role. Clear and eye-catching road signs can guide drivers to accurately judge the direction of travel and react to road conditions in advance, thus effectively reducing the occurrence of traffic accidents. In the many road safety facilities, solar road studs are with its unique advantages, become a bright new star in the modern road safety system. It not only provides key guidance for the road at night or in bad weather, but also has excellent performance in energy saving and environmental protection, contributing to our travelling safety and the construction of an environmentally friendly society. Today, we'll take a closer look at this innovative product.

At a time when global road construction is constantly developing, plastic solar road studs are increasingly attracting widespread attention due to their many characteristics. Combining advanced solar technology with high-quality plastic materials, they have demonstrated their ability to improve road safety and achieve energy-saving and environmental goals. Whether it's a busy city street or a remote village path, plastic solar road studs can play an important role. Next, we will start from its detailed specifications, significant advantages, global applications and other aspects of a comprehensive introduction, in-depth understanding of its unique charm and value.

Plastic solar road studs equipped with solar panels, is the core component of its efficient use of solar energy. For different battery types, there are precisely matched solar panel parameters. For example, the specification of the solar panel for Ni-MH batteries is 2.5V/120mA, while the specification of the solar panel for Li-ion batteries is 3.2V/500mAh. These solar panels are equipped with an excellent energy conversion ability, and their working principle is based on the photovoltaic effect. When sunlight hits the solar panels, photons interact with the semiconductor material to create electron-cavity pairs, which in turn form an electric current that efficiently converts solar energy into electricity. The electricity is then stably stored in the corresponding battery by means of a built-in circuit system. Thus, even at night or in poor lighting conditions, the studs can operate on the stored power and continue to illuminate and mark the road.

Plastic solar studs offer a wide range of options when it comes to battery configurations. Ni-MH batteries are available in 1.2V/600mAh, 1.2V/1300mAh, 1.2V/1500mAh and Li-Ion batteries are 3.2V/500mAh, which are suitable for different scenarios and needs. In areas where there is plenty of light and the studs are used less frequently, a smaller capacity battery may be sufficient to reduce costs and ensure basic use. In unstable light conditions or studs need to work for a long time in the place, high-capacity batteries can ensure a longer life. Nickel-metal hydride (NiMH) and lithium batteries have their own characteristics in terms of performance. Nickel-metal hydride batteries are relatively low cost and have a better cycle life; lithium batteries have higher energy density, are lighter in weight, and have a higher charging and discharging efficiency. Users can weigh the pros and cons and choose the most suitable battery configuration according to the actual situation.

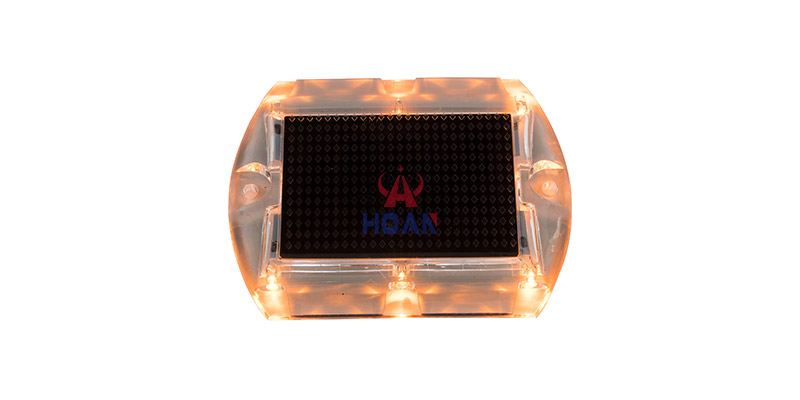

Plastic solar road studs have two practical working modes: flashing and constant light. In different road scenarios, these two modes play their own unique advantages. For example, in some dangerous areas that require special warnings, such as sharp turns and construction sections, the flashing mode can more effectively attract drivers' attention and remind them to drive carefully. On normal roads, the constant light mode provides drivers with continuous and stable road illumination to help them maintain the correct driving route.

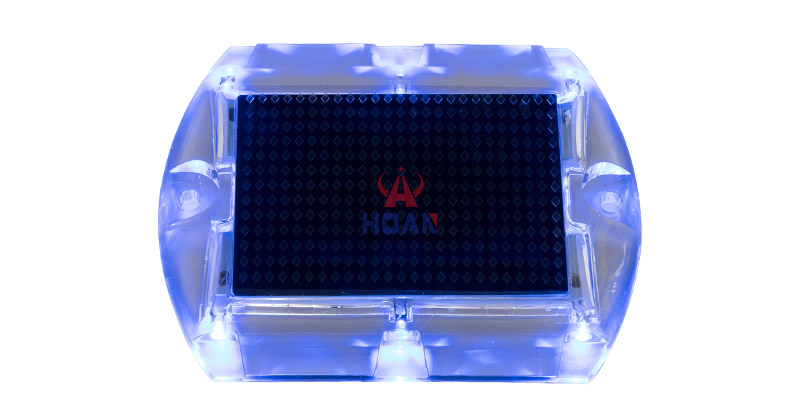

The six Φ5mm ultra-bright LEDs used in the road studs are the key to their high visibility. These LEDs are so bright that drivers can clearly see the light emitted by the road studs even from a distance. When driving at night, this high brightness provides drivers with sufficient reaction time to detect road conditions in advance and make appropriate driving manoeuvres in a timely manner, which greatly enhances road safety.

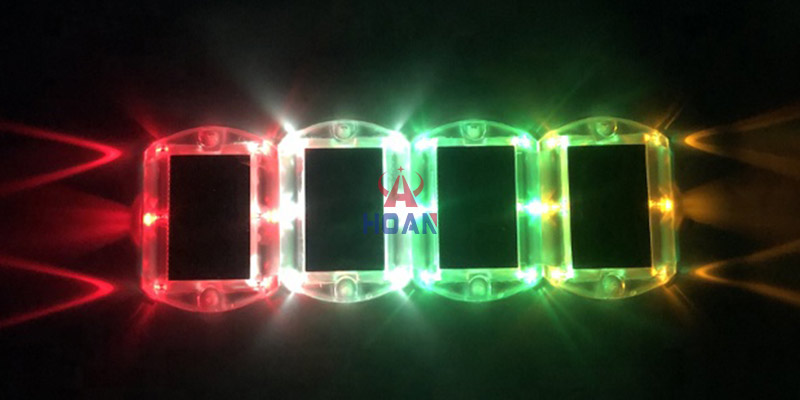

Plastic solar road studs are available in a wide range of colours including yellow, red, blue, green and white. Each colour has a specific meaning in road marking. Red is often used to warn of danger, and when drivers see a red road studs, they realise that there may be a hazardous situation ahead and that they need to take extra care. The colour green is often used to indicate a safe area or a permissible direction of travel. Yellow can be used to alert drivers to changes in road conditions ahead, such as approaching a junction or school zone. Blue is sometimes used for specific road facility markings. These rich colour choices can meet diversified road marking needs and make road information conveyed more accurately and clearly.

It is worth mentioning that plastic solar road studs have a visual range of over 800 metres. This means that at night or under adverse weather conditions, such as foggy conditions or torrential rain, drivers will be able to detect the light emitted from the road studs from a distance. Such a long visual range provides drivers with sufficient warning distance, giving them ample time to adjust their speed, change lanes, etc., thus effectively avoiding traffic accidents.

Plastic solar road studs have excellent waterproof, weatherproof and pressure-resistant properties. The waterproof rating is IP68, which is a very high waterproof standard. This means that the studs can work even when submerged under water for a long period of time, and there is no need to worry about damage to the internal circuits due to water ingress. In heavy rainstorms, there may be a lot of water on the road, ordinary road markings are easy to fail due to water immersion, while the plastic solar road studs can still operate stably due to its excellent waterproof performance.

In terms of weather resistance, road studs can adapt to the working temperature range of - 20 ℃ to + 60 ℃. Whether it is in the cold northern winter or the hot southern summer, it can operate stably. In the cold winter, low temperature will not affect its battery performance and luminous effect; in the hot summer, high temperature will not lead to deformation of the plastic material or degradation of the solar panel performance. This excellent weather resistance ensures that the road studs will work well in all kinds of harsh climatic conditions.

The road studs also has a compressive capacity of more than 10T. In daily traffic, vehicles frequently run over the road studs, if the studs pressure resistance is not enough, it is easy to damage. With its strong structure and high quality materials, the plastic solar road studs can withstand the heavy pressure of vehicles and is not easy to damage, ensuring stability and durability under frequent traffic crushing, greatly reducing the frequency of replacement and maintenance.

Plastic solar road studs adopt 122*25mm round design, this size and shape has many advantages in practical use. The round shape has no sharp edges, which prevents accidental injury to passing vehicles and pedestrians. On the road surface, round road studs are more evenly distributed and will not be easily damaged by uneven stresses on the corners, as is the case with square or other shaped road studs. Their compact, sleek shape blends well with a variety of road surfaces. Whether it is a flat asphalt road, or a certain texture of the concrete road, road nails installed will not affect the smoothness of the road, the vehicle driving on it will not produce a sense of bumps, to ensure the comfort of driving.

The characteristics of the plastic material gives the plastic solar road studs outstanding cost advantages. First of all, the plastic material is more lightweight compared to the metal material, which reduces the cost of raw material procurement. Plastic production process is relatively simple, does not require complex smelting and other processes, further reducing manufacturing costs. During transport, transport costs are also significantly reduced due to the light weight. Imagine a large-scale road safety project that requires the transport of thousands of road studs, if the studs weigh a lot, the transport costs will be a considerable expense. Plastic solar road studs, with their weight advantage, can save considerable transport costs for the project. Combined manufacturing and transport costs make plastic solar spikes a more cost-effective option, especially for road construction projects with limited budgets.

Plastic solar road studs are manufactured using high quality, weather resistant plastic. This plastic has excellent resistance to corrosion and is able to withstand rain, airborne chemicals, and other erosion of the road studs. Compared with metal studs, metal is prone to rust and corrosion under the action of long-term rain and chemicals, leading to performance degradation or even damage, while plastic spikes will not be in this situation, greatly extending the service life.

Plastic also has a strong resistance to ultraviolet light. In outdoor environments, road studs are exposed to sunlight for a long time, ultraviolet rays will make many materials aging, performance degradation. However, plastic solar road studs can effectively resist the erosion of ultraviolet rays and maintain the stability and performance of the material through special material formulations and surface treatment. Even after years of exposure to the sun, the colour, structure and luminous properties of the spike can still be maintained in good condition.

Under adverse weather conditions, such as heavy rain, snowstorms, sandstorms, etc., plastic solar road studs can also maintain stable work. In heavy rain, its waterproof performance to ensure that the internal circuit is not affected; in blizzard weather, low temperature will not cause damage to it; in the sandstorm, the plastic material is not easy to be worn by the sand. This stability in all kinds of bad weather reduces the frequency of replacement of road spikes and lowers maintenance costs in the long run.

The lightweight nature of plastic road studs makes them easy to install. Construction workers do not need to use large, complex mechanical equipment, only rely on manpower can easily carry and install the road studs. This greatly simplifies the installation process and saves installation time. Compared with the traditional road sign installation, traditional signs may require heavy equipment for lifting, fixing and other operations, not only the construction is difficult, but also the installation process is time-consuming. While the installation of plastic solar road studs, construction workers can quickly fix the studs in the designated location, greatly reducing the construction cycle. In large-scale road safety facility construction projects, the shorter installation time means that roads can be opened more quickly, reducing the impact on road traffic and improving the overall efficiency of the project.

The plastic material is inherently strong and durable, able to withstand frequent crushing by vehicles and daily wear and tear. Under normal use, the road studs are less prone to damage and deformation. This reduces the need for regular inspection and maintenance. Compared with some other road safety facilities, such as metal road studs may be deformed due to vehicle crushing, requiring regular inspection and correction; some electronic equipment type of road signs may require frequent maintenance due to circuit failure. In contrast, plastic solar road studs can be kept in good working condition with only occasional simple cleaning to remove dust and dirt from the surface during normal use. Its low maintenance cost advantage not only saves human and material resources, but also ensures that the road safety facilities can operate stably for a long time, providing continuous and reliable services for road users.

Plastic solar road studs perform well on a variety of road surfaces. On asphalt, the road studs can be firmly attached to the road surface by special glue or fixing device, and will not be easily loosened even if the vehicle is driven frequently. On concrete, too, a suitable mounting method ensures that the studs are firmly attached to the road surface. Whether it is a flat main road in the city or a slightly undulating path in the countryside, the plastic solar road stud fits in well. It can adjust its own installation angle and fixing method according to the smoothness and texture of the road surface, ensuring the best performance in all kinds of complex road environments, and providing drivers with accurate road markings and guidance.

The plastic material has been specially designed and surface treated to provide excellent reflective properties. In low-light conditions, such as at night or in foggy weather, when vehicle lights hit the plastic solar road studs, the studs are able to reflect the light back, creating a distinctive light marking. This reflective principle is based on the microstructure of the plastic surface and the reflective coating, which effectively focuses and reflects light in a specific direction, enhancing visibility. When travelling at night, drivers can clearly see the light reflected from the road studs, thus accurately identifying road contours, lane boundaries and danger zones. This excellent reflective performance plays an important role in ensuring road safety and greatly improves the safety of drivers in complex environments.

In the production process of plastic solar road studs, many recyclable plastic materials are used. When the spike has completed its service life, these plastic materials can be recycled. This feature reduces the generation of solid waste and lowers the pressure on the environment. Compared to some non-recyclable materials, plastic solar spikes offer significant environmental advantages. For example, traditional metal spikes are more difficult to recycle after disposal, and the recycling process may consume a lot of energy and resources. The recyclability of plastic solar spikes makes them have less negative impact on the environment throughout their life cycle.

At the same time, plastic solar road studs are powered by solar energy, which is a clean, renewable energy source. Compared with traditional road signs that rely on fossil energy to power them, solar road studs do not produce carbon emissions during use and do not pollute the atmosphere. This is highly compatible with the current global advocacy of sustainable development and environmental protection concept, contributing to the construction of an environmentally friendly society.

The application of plastic solar road studs is extremely wide. In parks, squares and other recreational areas, it can provide safety guidance for pedestrians. In the park trails, studs are laid along the road, even at night, pedestrians can clearly find the direction of travelling, to avoid getting lost or falling down because of not being able to see the road. In the plaza, road studs can be used to divide different functional areas, such as walking area, bicycle parking area, etc., to protect the safety of pedestrians and the order of activities.

At road intersections, plastic solar road studs play an important role. It can assist traffic signals and guide vehicles to travel in an orderly manner. In some complex intersections, the bright marking of the road studs can allow drivers to judge the direction of the lane more accurately, avoiding traffic accidents caused by misjudgment of the lane. For example, in some intersections without traffic islands, road studs can clearly mark the turning path of vehicles and improve the efficiency of traffic flow.

In car parks, road studs can be used to divide parking spaces and indicate the direction of travel. It can help car owners accurately find their own parking spaces, but also can guide vehicles in the car park in an orderly manner, to avoid collision and scratching between vehicles, improve the management efficiency and safety of the car park.

In special areas such as pedestrian crossings and cycle paths, plastic solar road studs can also enhance the marking effect. In pedestrian crossings, the flashing or constant light of the studs can attract the attention of drivers, reminding them to slow down and yield to pedestrians. In the bike lane, the studs can clearly mark the lane boundary, protect the safety of cyclists, make the distinction between the bike lane and the motorway more obvious, and reduce the safety hazards brought about by the mixing of vehicles.

Plastic solar road studs are widely used worldwide. In South Africa, a large number of plastic solar road studs are used in road construction projects to improve road safety. In some areas of South Africa, where the terrain is complicated and lighting conditions are limited at night, plastic solar road studs provide drivers with reliable road guidance at night due to their excellent performance.

In the United States, plastic solar road studs are widely used in a variety of road scenarios, whether it is the city's highway, or rural trails. The U.S. has a vast territory, and the climate and road conditions in different regions vary greatly, while the good adaptability of plastic solar road studs makes them useful in various environments.

Canada, the United Arab Emirates and other countries have also chosen plastic solar road studs. Canada's cold winter, plastic solar road studs low temperature resistance to ensure its normal work in the cold environment. In the United Arab Emirates, where the climate is hot, the stud's resistance to heat and UV rays meets local needs. In addition, Argentina, Indonesia, Martin ique, Cyprus, Chile, Colombia, the United Kingdom, Poland, Belgium, Australia, Russia, France, Singapore and many other countries, are also actively promoting the use of plastic solar road nails, its popularity can be seen.

Take a city in the United States as an example, in an important road connecting the city and suburbs, before due to insufficient lighting and road marking, traffic accidents occur frequently at night. After the installation of plastic solar road studs, the situation has been significantly improved. According to the local traffic department, within a year after the installation of the studs, the accident rate at night on this road dropped by 30 per cent. The clear markings and stable illumination of the studs allow drivers to judge road conditions more accurately at night and react in advance, which effectively reduces the number of accidents.

In a rural area of Australia, there is a winding mountain road, in the past due to the lack of effective road markings, often occurring vehicles off the road accidents. The installation of plastic solar road studs not only provides drivers with clear road contour guidance, but also sets up flashing red road studs at some sharp turns, playing a good warning role. Since the installation of the studs, the accident rate of the mountain road has been reduced significantly, and the local tourism industry has also been boosted as tourists can feel more at ease when travelling at night. These practical cases fully demonstrate the great application value of plastic solar road studs in improving road safety and enhancing traffic efficiency.

Through an in-depth understanding of the plastic solar road studs, we see that it shows significant advantages in many aspects. From the detailed specifications, its highly efficient solar panels, various battery configurations, practical operating modes, high brightness LEDs, a wide range of colour options, excellent waterproof weather resistance and compression resistance, as well as reasonable size and shape design, laying a solid foundation for its application in road safety. In terms of advantages, the cost advantage makes it an affordable choice, durable and strong weather resistance ensures long-term stable work, convenient and efficient installation saves time and manpower, low maintenance needs to reduce operating costs, suitable for a variety of road surfaces reflecting a wide range of applicability, excellent reflective properties to protect the safety of environmental protection concepts in line with the development trend of the times, and a wide range of application scenarios to demonstrate its versatility. These comprehensive advantages make it play an important role in enhancing road safety and promoting sustainable development.

We hereby call on road builders, municipal administrators, traffic planners and other relevant parties to actively use plastic solar road studs in road safety projects. It not only provides a safer travelling environment for road users, but also contributes to environmental protection. Let us act together to promote the upgrading of road safety facilities, to build a safer, more environmentally friendly and efficient road network to add bricks and mortar, so that the plastic solar road studs in the global road shine, lighting up the road people travel.